Maintenance was once referred to as the ‘necessary evil’ something to be done in order to tick boxes, but kept to a minimum in the name of cost reduction and inconvenience. But in highly legislative, safety-critical industries like rail, maintenance has always been integral to effective management of the network, and of paramount importance to keep trains on track and to reduce risk to both man and machine.

Today, the challenge of reconciling performance, reliability, availability, maintainability and safety with less finance, resource and time still remains. The pressures of delivering profitable operations that are safe and effective throughout the lifecycle are paramount.

Original equipment manufacturers are often challenged through standards and specifications to make life easier and to eliminate or simplify maintenance, whereas asset managers are tasked with ensuring the best value from the investment, whilst ensuring safety and reliability, but its the maintenance teams who keep things operational and perform more with less.

Engineers and asset managers know the importance of a good maintenance regime and how a planned intervention, performed at the right time is the key to a successful, reliable railway.

But how can this be achieved in less time, in a challenging trackside environment with fewer boots on ballast? The solution lies in remote condition monitoring.

What is Remote Condition Monitoring?

The days of sending engineers onto tracks, through rail traffic and hazardous terrain are increasingly limited. Exposing staff to the risks of the rail environment means working at the lowest level of the safety hierarchy.

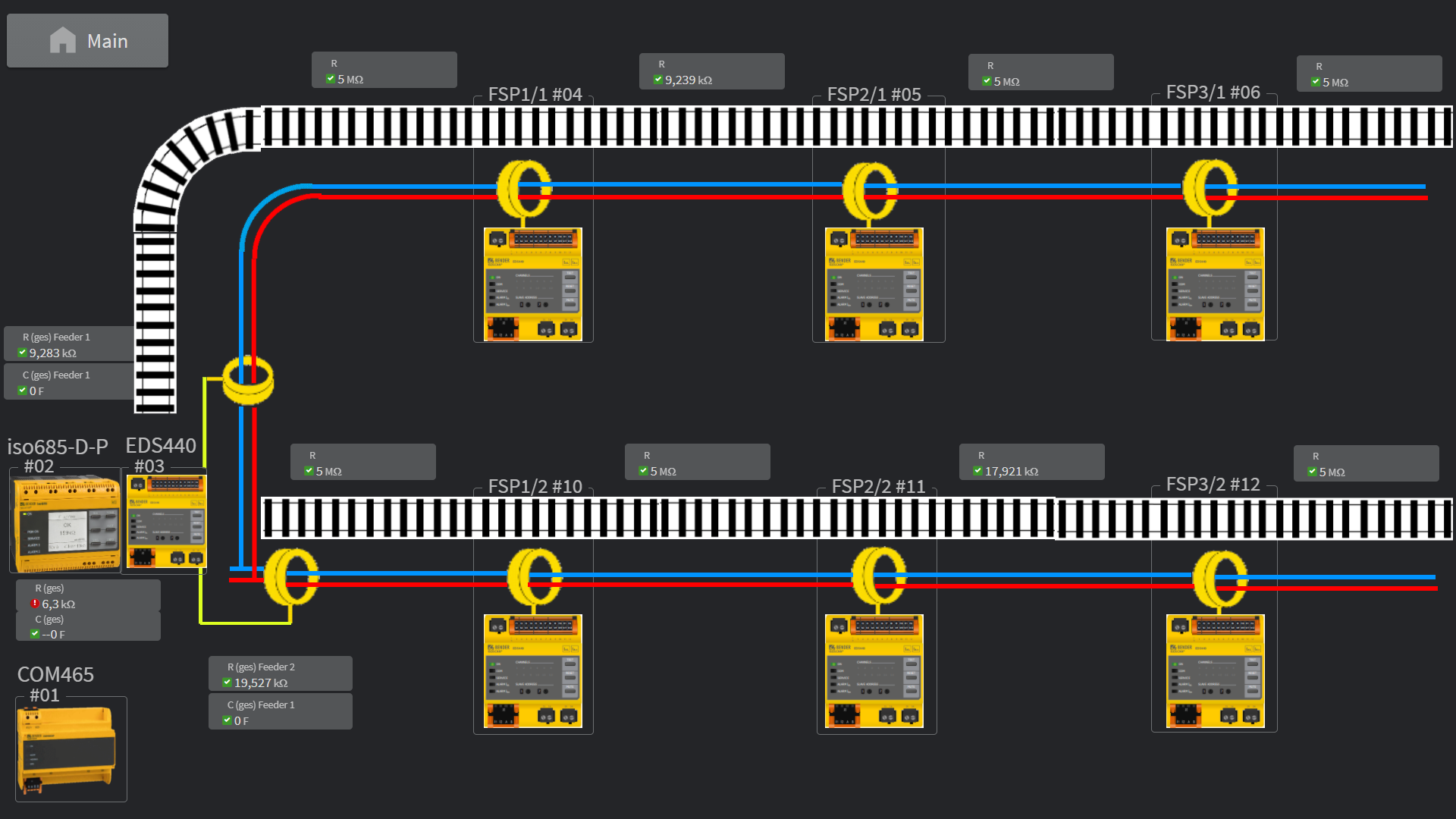

With Bender remote condition monitoring, networks can be monitored from a distanced location, to provide status and advanced warning of an assets condition. This increasing toolkit of data provides opportunities for new ways of working, analysis and risk reduction, that were previously unachievable.

Benefits of Remote Condition Monitoring - Save time, money and reduce boots on ballast

Innovations in monitoring technology, telecoms, Network Rail's transformation programme 'Intelligent Infrastructure', and remote condition monitoring have opened-up the possibility of finally reconciling the tensions between the needs for minimal intervention and continuous improvement in workforce and passenger safety. Remote condition monitoring ensures:

- Advance warning of asset condition

- Optimal asset performance and management

- Minimal system intervention

- Boots off ballast

- Passenger safety

- Reliability and availability of the network

Bender Remote Condition Monitoring

We have brought together the technology and process to introduce new solutions for railway maintenance. Reducing the need for boots on ballast, preventing trackside accidents and improving electrical safety of rail networks can be achieved whilst enabling a reduction capital outlay and running costs for operators.

Bender UK RS4 Tier 1 Technology enables the Network Rail to manage trackside power distribution safely, efficiently, and effectively without having to access the track at all.

Management of damaged or faulty cables

Benefits are far outweighed - engineers can monitor cables during the build phase of a project, and maintenance teams can manage existing systems to protect against rodent damage, cable theft, faulty installation, and cable degradation and avoid manual test cables for statutory periodic inspection and test based on NR/L2/SIGELP/50000.

Asset managers can confidently claim compliance to standards, maintain KPIs relative to service affecting failures and monitor the performance of the asset at any time. Historical data can be utilised to predict future degradation to accurately plan interventions and future maintenance.

Transform workforce safety

The operator gains train performance improvements from reduced power failure incidents overall and hugely improved delay per incident. Workforce safety is transformed by minimising the need to travel to site, access the trackside environment and work on electrical equipment and the whole range of hazards associated with this.

By providing bespoke, tailored solutions and data, engineers and asset managers can take action to predict and prevent failures in lineside and signalling power and distribution, build their asset condition knowledge and identify trends and patterns with the environment around the system being monitored, without having to leave the office.

Our commitment to rail innovation

Bender is committed to the investment in smart, railway technologies which support the railway’s drive for through-life cost savings, improvements in financial efficiency and to transform workforce safety through the implementation of proactive maintenance through Remote Condition Monitoring.

Tony Edwards

Rail Business Manager

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.