The maritime industry utilises many types of vessel such as defence warships, transportation fleet, cargo ships, cruise liners, luxury yachts and support vessels.

These ships must be able to withstand harsh operating conditions, often enduring lengthy durations in service at sea. Onboard critical electrical systems should be designed for maximum availability and resilience to protect against the risk of failure, fire and shutdown, any of which could prove to be catastrophic. Whatever the mission, the safety of crew and passengers is of paramount consideration when designing any marine vessel.

Ships Electrical Design

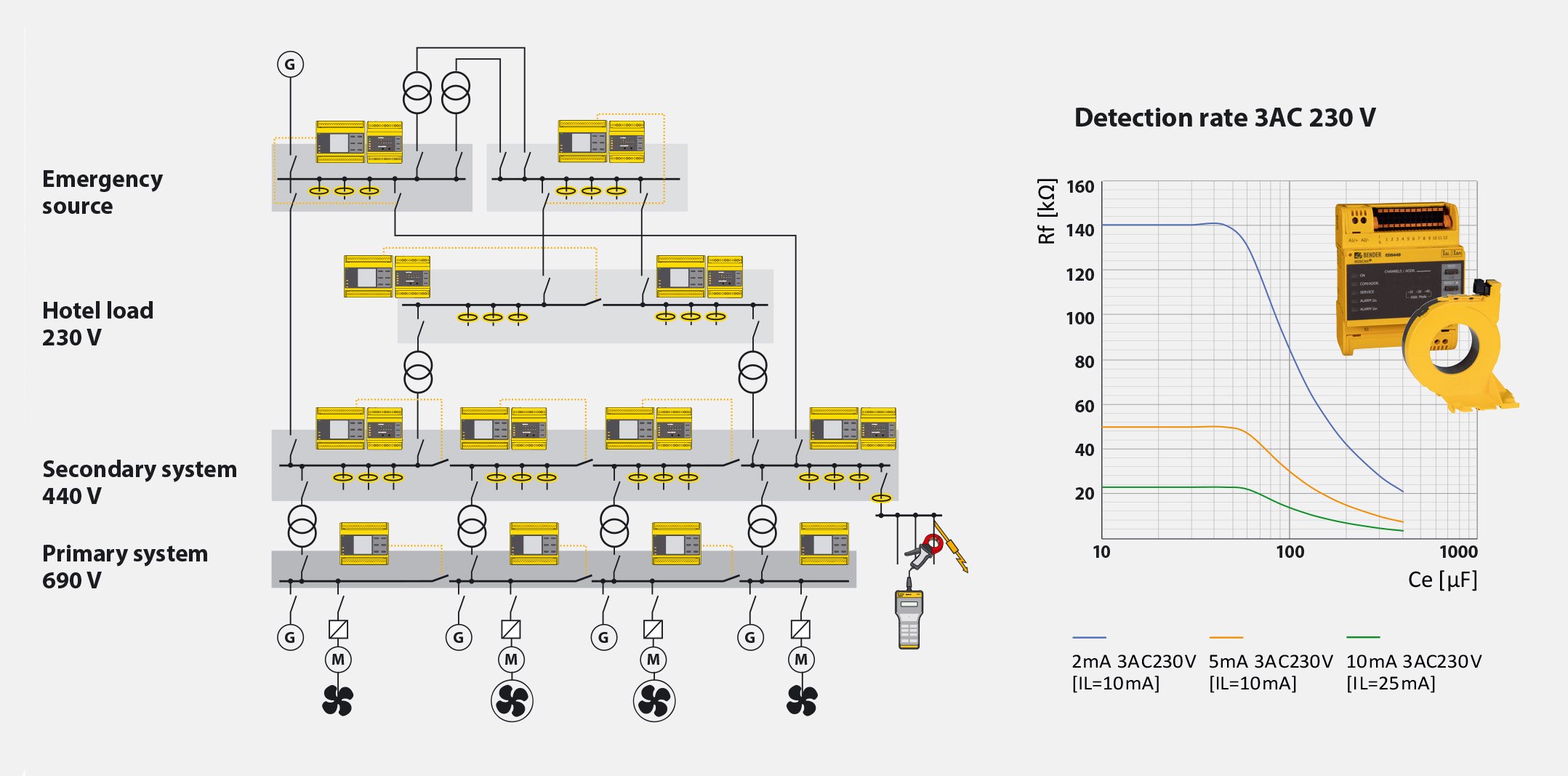

In naval engineering and shipbuilding, ships are often designed and built with unearthed electrical power systems. Onboard generators, distribution, propulsion, and control and automation systems are monitored in real time - online or offline, to forewarn of potential insulation degradation and protect against dangerous developing earth faults. If undetected these faults could have serious safety risks to equipment and personnel with potentially serious consequences - even resulting in environmental disaster. Therefore, the use of unearthed electrical systems (IT power systems) with insulation monitoring is crucial in the design of ships for maritime applications.

Sophisticated monitoring technology from Bender is designed for harsh marine conditions and is globally proven on vessels ranging from Navy warships, submarines, cruise liners to oil and gas FPSO's - offering protection against the dangerous consequences of electrical failure.

The challenge

Earth faults onboard ships are critical. Thankfully, any electrical system, whether critical or not, can be monitored so that developing faults can be communicated quickly. Detecting faults before a catastrophic failure happens, enables a predictive, planned maintenance regime, instead of responsive engineering action, which is more risky and time consuming.

A common challenge for ships maintenance engineers is the sheer size scale of the vessel and knowing when and where faults are going to occur. Maritime engineers responsible for maintaining the health and condition of electrical systems can rely on continuous monitoring and real time data from Bender systems to understand and react to accordingly. An unearthed IT power or control system with an insulation monitoring device (IMD) and fault location device (EDS) automatically alarms and locates insulation faults, directing crews to fault location, reducing the effort and time associated with manual fault finding.

Technology Scope

Insulation monitoring can be applied to different system types, easily handling high-frequency dc currents. This means electrical faults can be quickly detected and reported, reducing the time for preventative repairs to be realised. This is suitable for military warships where high-frequency supplies to radar, sonar and weaponry must be constantly available or always on. Bender technology can also monitor offline safety-critical loads such as fire-fighting equipment, emergency pumps and winches, which are periodically used, and often left unchecked until the next use.

Multi-channel residual current monitoring (RCM) can benefit areas supplied by earthed power systems which are prone to electrical faults, such as galleys, accommodation, and laundry services. These areas, though not as critical, can still be exposed to faults. RCM detects an emerging problem much earlier than manual examination, again allowing repairs to be carried helping to prevent the risk of electric shock or shutdown.

Bender has a history of innovation and in working to support critical maritime applications - helping to guarantee high availability and electrical safety onboard ships.

For more information on designing and incorporating systems with IT power systems visit our know-how pages or maritime solutions pages.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.